News

Transmission Technology

Oil has to flow, ideally through tubes

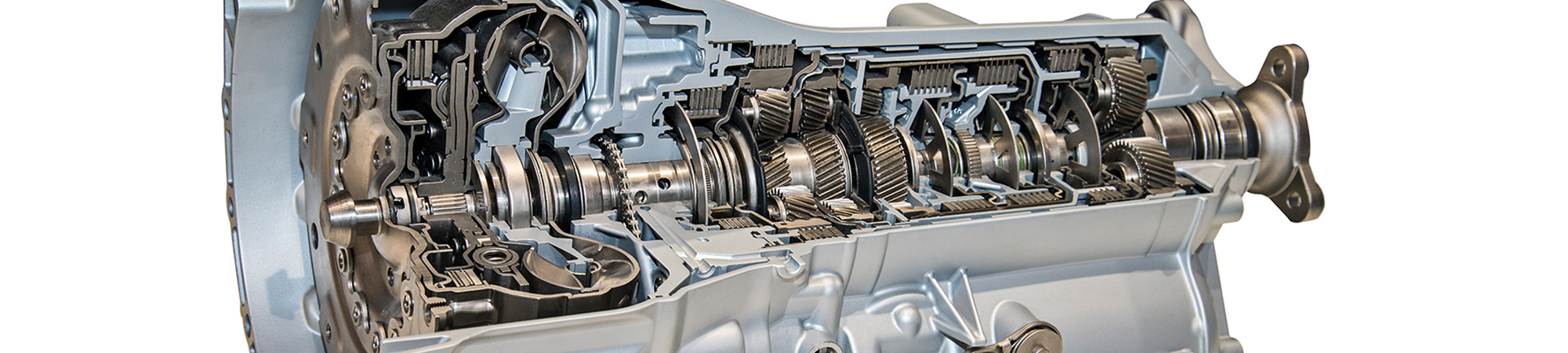

Transmission is one of the central elements in a vehicle. A malfunction of the assembly invariably leads to total failure. In order for a transmission system to work properly, the oil flow inside must be guaranteed.

And what does that have to do with KOHLHAGE? Modern transmission systems are always produced as pressure die-cast products. Following the casting process, oil flows are incorporated into the cast housing using milling technology. That costs time and is above all for one thing: expensive. KOHLHAGE technology replaces the costlier milling process.

Tubes are placed in the casting tool even before the actual casting process. The contours of the tubes correspond to the subsequent oil flow. While casting, the tubes are also moulded. Advantage for the gearbox manufacturer: The subsequent milling work is completely eliminated.

An additional feature speaks in favour of KOHLHAGE solution: In the past, when tubes were moulded, they had to be filled with salt or sand. In this way, unwanted deformations caused by the pressure during casting were avoided. Tube solutions from the KOHLHAGE house are designed to withstand the pressure. This means that there are no further costs for the laborious cleaning of the tubes. Needless to say, KOHLHAGE also advises specialists on the right choice of materials and the optimal coating of tubes.

That was the Fastener Fair Global 2025