News

Fluid technology from KOHLHAGE Automotive

The tolerance makes it leakproof

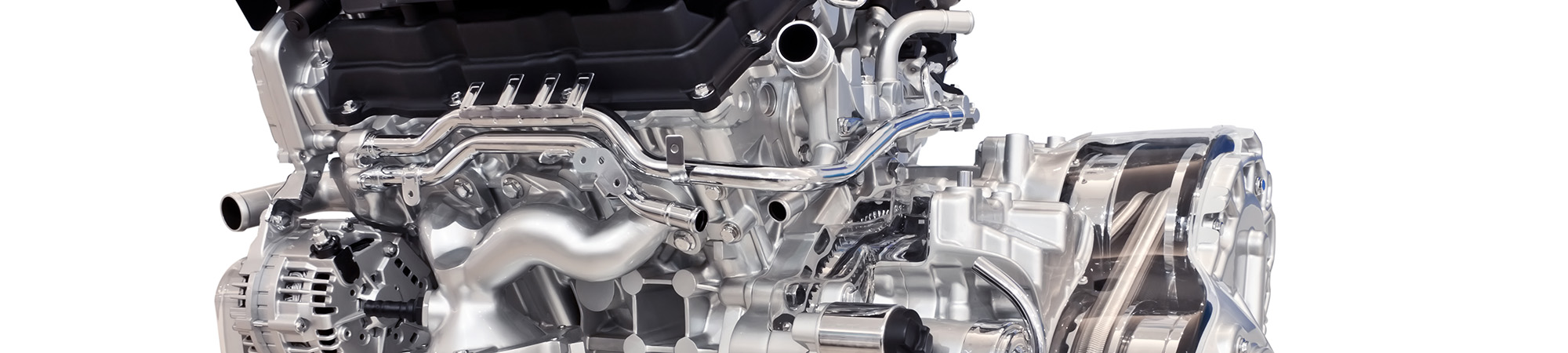

KOHLHAGE Automotive has been known for decades for the production of media-carrying tubes in the powertrain sector. The range of solutions from Neuenrade can be divided into two application areas with different complexity:

On the one hand there are tubes through which air or water is transported. Also included are differential pressure tubes through which engine exhaust gases are conducted to measuring points. Although these products are subject to strict quality requirements, they are rather uncritical in terms of safety. In contrast, pipelines in more complex applications through which fuel or oil is routed. These products are strictly evaluated in terms of safety, as failure can lead to danger to life and limb.

Both areas are connected by a prerequisite that is essential: Leak-proof. Nowadays, pipelines are increasingly being pressed when installed in other engine components instead of being glued, welded or soldered. This is because additional production steps cause additional costs. In order for a press-fit connection to be 100% leak-proof, tight tolerances must be maintained in production. These tolerance requirements have become more and more stringent in the automotive industry in recent years. KOHLHAGE, with its many years of production experience, can then meet exactly these tolerances and is therefore a valued partner.

Similarly narrow tolerances are required when hose assemblies are to be pressed onto tube sections. In this case the surface of the tube must be absolutely free of scoring, otherwise liquids can leak out from under the hose. KOHLHAGE also masters this facet of the production of fluid and oil tubes. It almost goes without saying for the KOHLHAGE experts that special techniques and experience are used to almost completely avoid the so-called tube collapse (minimizing the flow by reducing the inner diameter when bending).

That was the Fastener Fair Global 2025