News

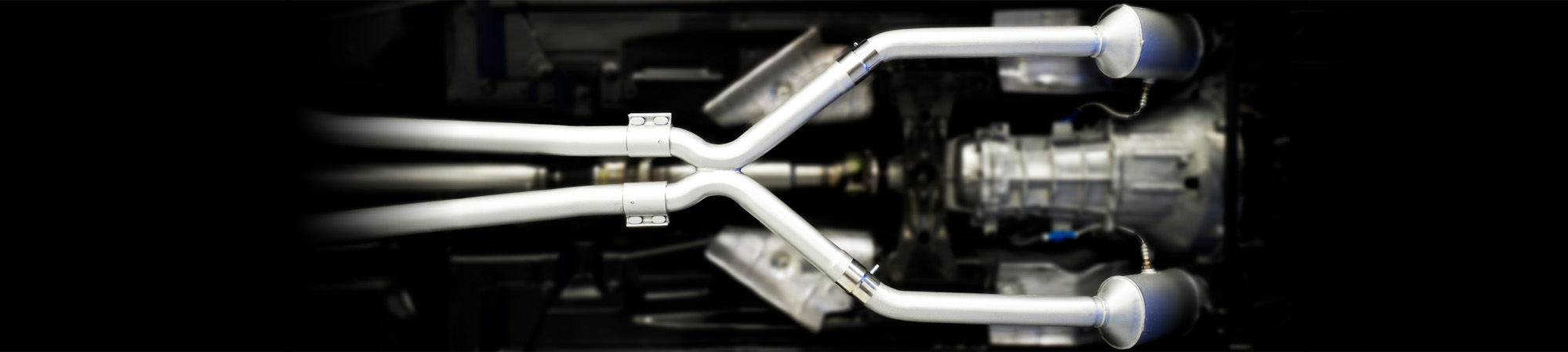

Emission technology from KOHLHAGE Automotive

Vacuum or electric?

Exhaust gas valves are installed in the rear silencers of modern vehicles today are usually driven by electronic means. Actuators that work with vacuum are relatively rare. For KOHLHAGE, this makes no difference, as the specialists there are proficient in both technologies. Much more important, however, is the fact that exhaust gas valves from KOHLHAGE have other significant advantages over a large number of competitor products:

Lower weight

KOHLHAGE exhaust gas dampers are designed as tubular assemblies. This makes them considerably lighter than those made of die-cast.

Higher temperatures

KOHLHAGE exhaust flaps can withstand temperatures of up to 900 °C due to their design. This is particularly important for high-performance applications.

Low part count

KOHLHAGE exhaust gas dampers are configured and manufactured on the basis of a modular design principle. This leads to an optimum common parts strategy.

Low volume

The tooling costs alone for die-cast products are so high that small and very small batches cannot be produced economically. At KOHLHAGE, the smallest series production starts at approx. 1000 pieces. KOHLHAGE is therefore the ideal partner for vehicle manufacturers who want to produce unusual models on such a scale.

That was the Fastener Fair Global 2025